What problems should be paid attention to in the use of double head hydraulic pipe bender

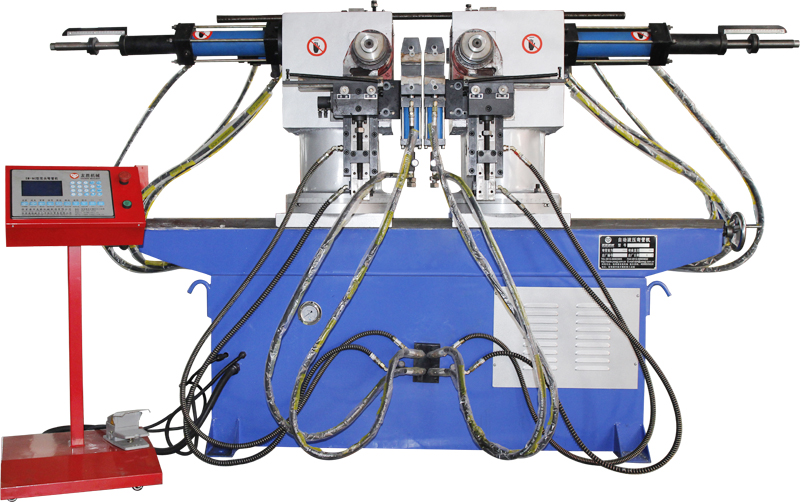

Double head hydraulic pipe bender can be seen everywhere in life. Its advantages include multiple functions, reasonable structure, simple operation and so on. But after all, they are machines, because they are planned to use zigzag metal, which is dangerous. If they are not operated properly, they will be dangerous. The double head hydraulic pipe bender drives the main shaft directly from the upper part of the machine head. The equipment is easy to protect. The main shaft of the pipe bender and the transmission sprocket are all cast, all processed, all hobbed, keyless connection and uniform stress. It is driven by double oil cylinders. In the process of pipe bending, the rotating arm is close to the viewpoint set for bending, and the hydraulic system actively saves buffer, which greatly improves the bending accuracy and quick reset, A saving buffer is set near the starting point during the return process, which greatly improves the reset accuracy and work efficiency.

1. Bending machine body: the machine body adopts channel steel welded spindle structure, and the upper and lower bearing support plates of the spindle are installed in the structure with 15mm thick steel plate.

2. System part: the hydraulic system part can be civil accessories or aircraft hydraulic accessories.

3. Transmission part: the transmission part is composed of oil cylinder, rack, gear and transmission shaft.

4. Mold part: the mold part is an auxiliary tool manufactured according to different surface diameters. It is made of bearing steel or roll steel and heat treated with hrc48 ~ 52.

5. Clamping part: the hydraulic clamping part is composed of sliding plate, rocker arm and hydraulic oil cylinder. The elasticity of the oil cylinder drives the rocker arm to move.

6. Electrical part.

The microcomputer controller can preset 16 viewpoints, and the pedal switch of the pipe bender can be used to complete the whole process. The stiffeners at the head and bed of the pipe bender are planned and annealed to eliminate the internal stress. All have the strength and rigidity to meet the requirements and prevent deformation. When the main shaft of the double head hydraulic pipe bender is equipped, it is directly pierced from the upper part of the machine head. The equipment is convenient for protection. The main shaft of the pipe bender and the transmission sprocket are all cast, all processed, all hobbed, keyless connection, uniform stress, and driven by double oil cylinders. During the pipe bending process, the rotating arm is close to the point of view set by the twists and turns, and the hydraulic system actively saves buffer, which greatly improves the accuracy of twists and turns, and quickly resets. In the process of returning, a saving buffer is set near the starting point, The reset accuracy and work efficiency are greatly improved.